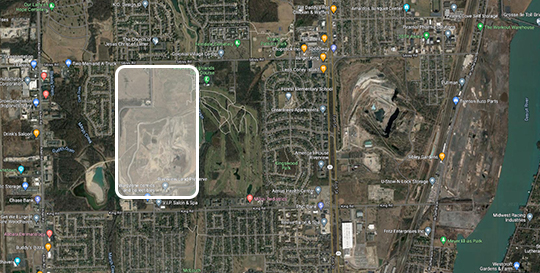

A short drive south of downtown Detroit is the Riverview Land Preserve, an approximately 400-acre solid waste landfill opened in 1968 that presently receives around 2,500 tons of trash a day.

It’s a dynamic site with private homes, public spaces and local waterways all in close proximity.

Consider its geography:

- Residential neighborhoods are immediately adjacent to parts of the property’s southern, western and northern boundaries

- An active municipal golf course borders its entire eastern boundary

- A handful of creeks and ponds are nearby, and the site is just two miles from the Detroit River

Approved daily cover material at the site included soil, wood chips and recycled tire chips. Soil had been the primary material; wood and tire chips were used if bad weather made earthwork impossible.

But unique circumstances in 2018 led site management to search for a better daily cover system. What sort of system that would be was still up in the air.

The circumstances

At the time, one cell at Riverview was actively receiving trash. Operators already knew where the next cell would be, but it was not yet approved for operations.

Here was the problem: Space was running out in the active cell. Regulatory approval for the new cell had not been granted. Not only was space in short supply, but without excavation in the new cell, the site was becoming dirt poor very quickly.

As a last resort, operators were forced to use clean fill from a borrow pit to perform daily cover. This was far from ideal because the borrow pit is located off-site, requiring added cost and transportation time. That soil also was initially earmarked for final capping of the almost-full cell and not for daily cover. They needed an alternative quickly to preserve the space available in the active cell.

As a stop-gap measure, Riverview purchased a tarp system to buy time for leaders to settle on a permanent alternative.

But Riverview also faced another challenge that landfill operators everywhere know all too well: Relying on soil daily cover is time- and labor-intensive and puts exceptional strain on heavy equipment like dozers, backhoes and dump trucks.

Atmos’ ADC foam demo sealed the deal

By 2019, the search for an alternative daily cover system had taken site operators across the country to see various options in action.

But one particular demonstration in northeast Pennsylvania stood out. The system on display there looked like it would work at Riverview. The only hurdle left was verifying with Michigan regulators that this was an approved alternative cover method. It was.

The equipment arrived at Riverview on a trial basis in March 2020 and has remained in place ever since. According to Riverview Land Preserve Operations Manager Kevin Sisk, the system’s impacts on operations were immediate and far-reaching.

By switching to the foam daily cover, Riverview Land Preserve:

- Slashed combined man and machine hours on daily cover operations to a fraction of what it had been

- Dramatically reduced daily wear and costly maintenance on its fleet of heavy equipment

- Made reductions in their labor force

- Redirected its remaining labor force to complete a wider range of other projects more quickly

A key component of working with Atmos is our unique model providing the state-of-the-art application equipment free of charge with the purchase of chemicals. This frees up funds for the site to allocate to other capital projects that may arise.

As a result of this transition, Riverview runs more efficiently, has cut costs and can conduct advanced project planning instead of merely reacting to day-to-day site needs.

Good thing, too. Another challenge was around the corner.

Odor control rounds out turnkey solution

As in many solid waste landfills, the Riverview Land Preserve contains several wells as part of its gas collection and control system.

The wells are designed to collect and flare landfill gases to eliminate unpleasant smells, but as they fail they operate less effectively.

Later on in 2020, after the foam cover system had arrived on-site, some of the gas wells at Riverview came due for replacement. As that work commenced, so did odor complaints from nearby residents.

Riverview approached our team to see if we could help.

After visiting a site where we had installed an odor neutralizing system, Riverview decided it was the right solution. Same as the foam cover system, it would be leased under a usage agreement so Riverview would not need to incur a capital expense.

The system was installed at the top of the hill with the fan blowing the mist directly over the area where the well work was underway.

It did its job: Atmos’ odor neutralizers helped eliminate the malodors at their source. Odor complaints from Riverview’s neighbors fell off drastically. The site also utilized Atmos’ odor neutralizers to stem odors emanating from the landfill working face. The linear misting system was set up on the perimeter of the working face to prevent working face odors as garbage was deposited into the cell.

Riverview is optimistic that Wayne County and the Michigan Department of Environment, Great Lakes, and Energy will approve a pending application for expansion, partly on the strength of the site’s effective daily cover and odor control regimen.

A service-always mindset

Riverview Land Preserve became an Atmos customer because they saw proof that its alternate daily cover worked in the field. Then, with the installation of the multiple odor neutralization systems, a partnership was born.

The service is there. It’s a rarity in this business.

If you’re searching for a partner who will put problem solving — and not selling — at the top of their list, give Atmos Technologies a look.

Daily cover in a solid waste landfill is a capital-intensive operation.

Generally, at a minimum, three large pieces of equipment are required: a backhoe, a bulldozer and a dump truck.

What if one of those breaks down unexpectedly? And what if replacement is the only solution? Is there room in your CapEx budget to buy new equipment on short notice?

Probably not. At least, not without forcing cuts to other critical budget lines like spare parts or equipment maintenance that are just as critical to daily operation.

Public and private landfill owners alike must make brutal decisions like this every day. When needs outstrip finite resources, they must pick winners and losers.

But it doesn’t need to be that way if you take these two simple steps:

- First, switch from topsoil daily cover to foam daily cover. We’ll cover why foam daily cover is a greener, more cost-effective option at the end of this article.

- Second, partner with a full-service equipment provider that offers a wide array of financing options. Instead of buying it outright, our equipment can be leased monthly or even provided under a zero-cost lease with a longer term commitment.

As you’ll read below, these simple changes will put important operational and fiscal control back in your hands.

Your CapEx budget is not a suggestion

For individual solid waste collection sites, it’s practically etched in stone.

Companies and municipalities operating landfills, transfer stations and fleets of heavy equipment nationwide make their margins on volume. Understandably, decision-makers always keep a tight grip on the checkbook. They fight hard enough as it is to get the capital allowance they’re given. Going back and asking for more is a boxing match that the house usually wins.

Only in extraordinary circumstances is a corporate officer likely to agree to buy a new bulldozer or dump truck that wasn’t already on the list of planned capital expenses. And even then, there’s no guarantee that the unplanned expense won’t require the sacrifice of something else that was already planned and approved.

But while corporate management has capital budget authority, they exercise much less control over individual sites’ regular operating expenses. In this realm, landfill managers have much more freedom to maneuver.

A flexible leasing theoretical

So, say a bulldozer on its last leg breaks down and your mechanic tells you it’s beyond repair. The short-term consequence? Your crew can’t open or close the site as quickly as you need to each day. They’re either starting earlier in the morning and staying later at night or restricting the volume of waste that can be collected each day as the site opens later and closes earlier.

The former drives costs skyward. The latter restricts daily revenue. Sometimes, both happen at once.

Long-term, you expect more of the same day after day unless corporate signs off on an unplanned capital expense. Even if they say yes, how long would it take to get an answer? Can you afford to wait?

Leasing the daily cover equipment you need — and tucking it under the operational expenses on your balance sheet — is a compelling opportunity in this case.

First of all, it’s just a better daily cover method.

Second, when providers offer equipment as part of the cost of the cover product, they own the asset and its associated maintenance costs. It’s their capital expense, not yours. And landfill general managers no longer need to worry about robbing Peter to pay Paul. Crucially, they can make this decision on their own instead of kicking it up the chain.

The challenge for government-owned landfills

If you think it’s hard squeezing an extra few hundred grand out of your board of directors, imagine shaking down your neighbors instead.

There is no rainy day fund available for government bodies bound by law to spend only what they need and not a nickel more.

If equipment breaks down and requires an urgent, unplanned expense, public owners have three options, all of them bad:

- Rob the required cash from some other line item in the budget

- Do nothing and muscle through it

- Return to council chambers and hope taxpayers are feeling generous

When we joke that it takes an act of Congress for these sites to make unplanned capital equipment expenses, it’s only a little bit of an exaggeration.

State-of-the-art, all-in-one foam application equipment from Atmos is available at a zero-cost lease to reduce fiscal pressure and provide more budgetary predictability for cash-strapped, taxpayer-supported entities.

As an added benefit, foam daily cover is a faster, cheaper and greener daily cover method. Learn more below.

Other operational benefits of foam daily cover

The leasing model we propose is far from just a way to sidestep the challenges you face in emergencies.

By leasing our foam daily cover equipment instead of owning traditional operations equipment, you can permanently direct a huge chunk of your capital allocations toward items that never seemed to rise to the top of the priority list, including building renovations and expansions or upgrades to utilities or roads.

Totally apart from the greater financial control you gain when you lease Atmos’ foam daily cover system, it’s a superior cover method for a variety of reasons:

- Foam is a lower-cost alternative to soil, especially in dirt-poor locations.

- Soil is capital-intensive and labor-intensive to spread. It requires several pieces of company-owned heavy equipment and several hours of wear and tear on the equipment and the labor to operate them.

- Soil must be scraped off the working face before receiving waste or the site has lost six inches of airspace forever.

In contrast, foam daily cover:

- Requires only one operator for about one hour a day

- Utilizes no air-space

- Requires no scraping or clean-up

When operators choose foam daily cover from Atmos, we own and maintain all equipment. The burden is on us, not you.

Learn more about foam daily cover from Atmos Technologies here.

When you’re flexible, you’re strong

Too often, an inflexible equipment procurement model paints landfill operators into a corner.

It forces them to pick winners and losers or takes decisions out of their hands entirely. Either way, that takes the efficiency out of a landfill’s daily operations. Where efficiency goes, profit follows.

Flexible financing makes the transition to foam daily cover simple and pain-free. Working with Atmos Technologies gives landfill general managers the freedom they need to maintain operational efficiency and make the most impactful use of the capital dollars they fight so hard for.

If you’re thinking of making a change, tell us more about your site.

Want a demo? Schedule one here.